The Benefits Of Using An Oil Water Separator In Your Industry

If you’re in the industrial industry, then you know that oil and water don’t mix. This can be a huge problem if they come into contact with each other, as the oil will contaminate the water and make it unusable. That’s where an oil/water separator comes in! This device is designed to remove oil from water, so that the water can be safely used again. In this blog post, we will discuss the benefits of using an oil/water separator in your industry. We’ll also talk about how they work and some of the different types that are available.

What is an oil water separator?

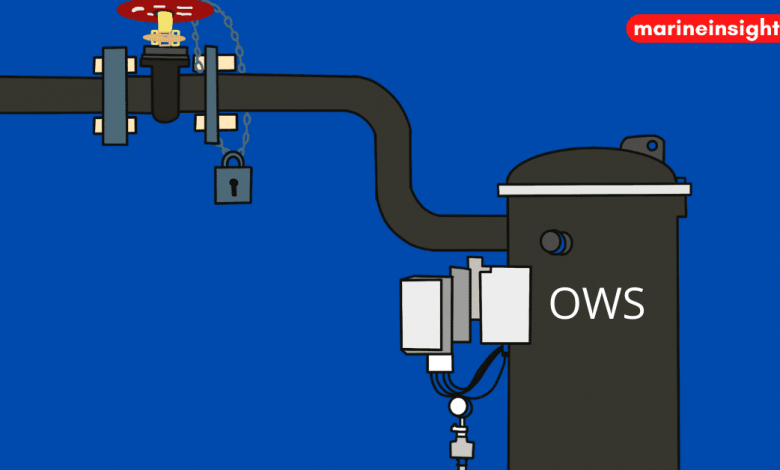

An oil water separator is a piece of equipment that is used to separate oil and water mixtures. The separated oil can then be reused or disposed of, while the water is returned to the environment.

There are many different types of oil water separators, but they all work on the same principle. Oil and water do not mix, so when they are forced to flow through a separator, the oil will float to the top while the water remains on the bottom.

Types of industries in which oil water separators can use

Oil water separators can be used in a variety of industries, including:

– Petroleum production: Oil water separators are used in petroleum production to remove oil from water so that the water can be reused.

– Automotive: Oil water separators are used in the automotive industry to remove oil and other contaminants from water used in car washes.

– Manufacturing: Oil water separators are used in manufacturing to remove oil and other contaminants from water used in various processes.

– Food and beverage: Oil water separators are used in the food and beverage industry to remove oil and other contaminants from water used in processing and packaging.

– Power generation: Oil water separators are used in power generation to remove oil and other contaminants from water used in cooling towers.

-Oil refining: Oil water separators are used in oil refining to remove oil and other contaminants from water used in the refinery process.

– Pulp and paper mills: Oil water separators are used in pulp and paper mills to remove oil and other contaminants from water used in the pulping process.

The benefits of using an oil water separator in your industry include:

– oil and other contaminants are removed from the water, making it safer for reuse;

– less oil is discharged into the environment, reducing pollution;

-Cost management/cost-effectiveness

Benefits of using oil water separators for industries

Some of the benefits of using an oil/water separator in these industries include:

– Increased safety: Oil and water don’t mix, so separating them helps to prevent dangerous accidents and explosions.

– Improved efficiency: By removing water from oil, separators can help increase the efficiency of industrial processes.

– Reduced environmental impact: Oil/water separators can help to reduce the amount of oil pollution in our environment.

– Cost savings: Using an oil/water separator can save money by reducing the need for disposal and clean-up of oil-contaminated water.

If you’re involved in any of these industries, an oil/water separator could be a valuable addition to your business. Talk to a separator specialist to learn more about how one could benefit your particular industry.

Find the best oil water separators from GPSenvironmental: https://gpsenvironmental.com.au/oil-water-separators/

Conclusion

An oil/water separator can be a valuable piece of equipment for any industry that deals with oil and water. By separating the two liquids, it can help to keep your operations clean and safe while also protecting the environment. If you are looking for a way to improve your business, an oil/water separator may be the answer.

For more valuable information visit this website